Our laboratory is equipped with devices for the preparation of bulk materials and coatings and instrumentation for a basic characterization of polycrystalline materials – phase analysis and optical properties. Other ways of characterization can be performed within the Department of Inorganic Chemistry (Instrumentation of the Department) or in cooperation with other institutions.

- Spin-coater, dip-coater

- Vacuum furnace up to 1700 °C and 10–7 Pa

- High-temperature furnace for the synthesis of solids

- High-temperature furnaces for the synthesis of solids with a controlled atmosphere

- Glove box

- X-ray diffractometer for polycrystalline materials

- X-ray fluorescence WD spectrometer

- Fiber spectrometer for the UV-Vis range

Spin coater

Our laboratory is equipped with a spin-coater type WS-650SZ-6NPP / LITE from Laurell Technologies Corporation.

Technical parameters

| Atmosphere | Nitrogen (vacuum system for substrate attachment) |

| Ramp / rotation / stopping time | 1 s – 99 h 59 min |

| Substrate rotation speed |

1 – 8,000 rot. min–1 |

| Acceleration / deceleration | 2 – 10,000 rot. min–2 |

The spin-coating method is used to deposit thin films of a thickness ranging from nanometers to micrometers onto flat substrates. The films are prepared from volatile solutions or suspensions. The method is widely used in both laboratory and industrial spheres. The principle is to apply a small volume of solution to the center of a horizontally attached substrate and then to rotate it up to several thousand revolutions per minute. Centrifugal forces cause the solution to spread evenly over the entire surface of the substrate, with the excess of the solution flowing over its edge. When applied repeatedly, a thin film is produced.

The spin-coating method is used to deposit thin films of a thickness ranging from nanometers to micrometers onto flat substrates. The films are prepared from volatile solutions or suspensions. The method is widely used in both laboratory and industrial spheres. The principle is to apply a small volume of solution to the center of a horizontally attached substrate and then to rotate it up to several thousand revolutions per minute. Centrifugal forces cause the solution to spread evenly over the entire surface of the substrate, with the excess of the solution flowing over its edge. When applied repeatedly, a thin film is produced.

By subsequent annealing, a crystalline film with desired properties can be prepared. The great advantages of this method are low technological difficulty, simplicity and reproducibility.

Dip coater

Our laboratory has a dip-coater type RDC21-K from Bungard Elektronik GmbH.

Technical parameters

| Working atmosphere | air |

| Maximum substrate weight | 5 kg |

| Maximum lift height | 580 mm |

| Handling speed | 3 – 7,000 mm min–1 or 1.5 – 3,500 mm min–1 |

| The speed of immersion / pulling | 3 – 2,500 mm min–1 or 1.5 – 1,750 mm min–1 |

| Dive / pull time | 1 s – 99 h 59 min |

Dip-coating is a method that allows a thin layer to be prepared on both sides of a substrate at once. The principle of the method lies in the vertical immersion of the substrate into the solution for a certain period. Subsequently, the substrate is emerged with a defined velocity, with the excess solution flowing back into the vessel and evaporating the excess solvent. Repeating the wetting cycles of the solution results in a thicker layer that remains on the substrate surface. Sometimes the wedge effect can be observed, which is an asymmetry in the thickness of the layer on the bottom and top of the substrate. The deposited layer is further heat-treated. The dip-coating method is characterized by its low financial demands and easy preparation of the layers.

Dip-coating is a method that allows a thin layer to be prepared on both sides of a substrate at once. The principle of the method lies in the vertical immersion of the substrate into the solution for a certain period. Subsequently, the substrate is emerged with a defined velocity, with the excess solution flowing back into the vessel and evaporating the excess solvent. Repeating the wetting cycles of the solution results in a thicker layer that remains on the substrate surface. Sometimes the wedge effect can be observed, which is an asymmetry in the thickness of the layer on the bottom and top of the substrate. The deposited layer is further heat-treated. The dip-coating method is characterized by its low financial demands and easy preparation of the layers.

High-temperature furnace for solid phase synthesis

- Tube furnace for sintering in vacuum (up to 10–7 Pa) or in a chosen atmosphere, up to 1700 °C

- Muffle furnaces for temperatures up to 1600 ° C (air) and tube furnaces for sintering in diferent atmospheres (up to 1200 °C)

|

|

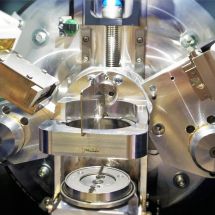

X-ray diffractometer for polycrystalline materials

Bruker-Phaser 2nd Generation XRD for polycrystalline samples

- Diffractometer with Co X-ray lamp ( λ [Co K-α1] = 1.789 · 10–1 nm)

Cu lamps as an X-ray source are also available at the Department of Inorganic Chemistry.

|

|

X-ray fluorescence WD spectrometer

SPECTROSCAN MAKV-GVM (Spectron)

Sequential wavelength dispersive X-ray fluorescence spectrometer for elemental analysis of powders, films, pelets, pearls and liquids in the range of Na-U.

- Pd X-ray lamp with a max. power of 160 W

- 4 analyzing crystals (LiF, graphite, PET, RbAP) in a Johanson geometry

- Xe gaseous proportional counter detecting simultaneously in two orders of spectrum

- sample changer with 10 slots